To break the technical bottlenecks of high precision, complex shape, difficult mechanical machining and difficult determination of EDM process routes for special material closed structure twisted cavity parts, after years of tackling key problems, the project has resolved key technical problems such as processing technology, pulse power supply and functional components, and successfully finished the processing of nearly 100 integral closed impellers and turbine disks with blade crowns over 20 models, in which the technical parameters have reached the international level of similar products. The processing of three-dimensional closed impellers with the large specifications has been completed, which lays a solid foundation for developing high-efficiency compressors for all types of energy devices while reduces the manufacturing costs. The project achievement have promoted the technological progress of EDM, improved the machining level of the whole closed impellers in China, and reached and approached the world advanced level in technology. It solves the problems of aviation, aerospace and Energy Field machining, promotes the improvement of product technology level, has obvious economic and social benefits, and possesses high promotion value.

The popularization and application of the project achievement has comprehensively raised the level of manufacturing technology in key fields in China: (1) It provides an efficient, energy-saving and environment-friendly processing method for twisted cavity closed structure parts, which boasts a bright market prospect and a striking social benefits; (2) It has driven the technological progress of the industry, upgrades the level of special processing technology industry, extends the industrial chain and facilitates the progress and development of the industry. This technology has expanded the application range of special processing technology, facilitates the development of special processing industry, consolidates the indispensable position of special processing in manufacturing field, and testifies that special processing is the most effective means to achieve the precision machining of special material closed structure distorted cavity parts. This technology is applied in high-end industry, which extends the industrial chain of EDM technology application and raises the level of EDM industry. Machining technology has been successfully developed and advanced technologies (CAD/CAM, finite element simulation, multi-body kinematics simulation, etc.) of modern science and technology have been fully utilized. On the basis of in-depth study of EDM parameters and equipment, the combination of EDM technology and other advanced technologies has been expanded, which promotes the development of EDM technology faster and better and enhances the service level of EDM technology. (3) The process technology and equipment play positive promoting roles in the development of significant areas, which can tremendously cut down the production costs and resource consumption of related products, produce excellent environmental benefits, and exert an important influence on raising the level of sustainable development of the industry, the level of manufacturing industry, the technological progress of enterprises, as well as product upgrading and social development.

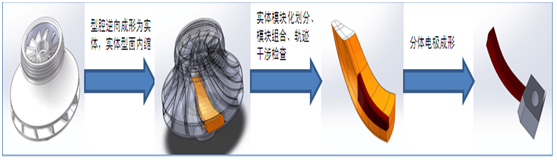

Schematic Diagram of Machining

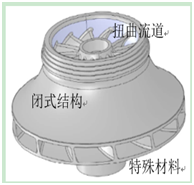

Difficulty of Integral Closed Impellers

Design method of split electrode based on cavity reverse forming and module combination

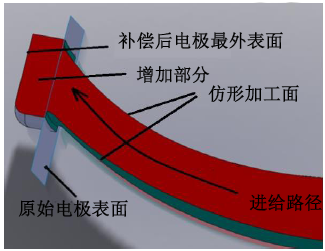

Schematic Diagram of Electrode Incremental Compensation Design

Intellectual Property Rights:

There are 4 invention patents, 3 utility model patents, 14 papers and 2 volumes of standards have been obtained in this project.